1.) DEFINITION

“Advanced Product Quality Planning” (APQP) is a comprehensive, continuous approach based on project management methodology.The goal of this approach is to ensure the comprehensive product planning or a change to the product and ultimately the control that all phases of the product realization are completed on time and quality as agreed.

The normative basis for APQP is AS/EN 9145 “Requirements for Advance Product Quality Planning and the

Production Part Approval Procedure”.

APQP according to AS/EN 9145 adapts to the product development process as follows. It:

- ensures that all activities are performed on schedule and to quality standards;

facilitates effective communication; - enables timely resolution and removal of obstacles;

- requires proactive approach to mitigate risks in the Product Development Process;

- it integrates the supply chain into the product development process in a controlled manner.

APQP supports the product development process (PDP) and:

- applies to each component of the PDP;

- standardizes deliverables for each APQP phase;

- evaluates runtime based on the timing and quality of required deliverables using reviews (e.g. PDR, CDR, etc.).

Depending on the project, different standard methods (FMEA, QFD, QM plan, etc.) can be applied. Their use can help to standardise the results of the assessments, whereby individual points can be varied or deferred.

The elements and phases of APQP are compatible with the requirements of (EU) 748/2012, Part 21, and can be used as a project management approach to manage the meeting of these specific requirements in a meaningful and structured way.

In practice, APQP has not only demonstrated its effectiveness in the management of product development processes at suppliers of aircraft manufacturers. APQP can also be successfully applied to the development of complete aircraft or their modifications.

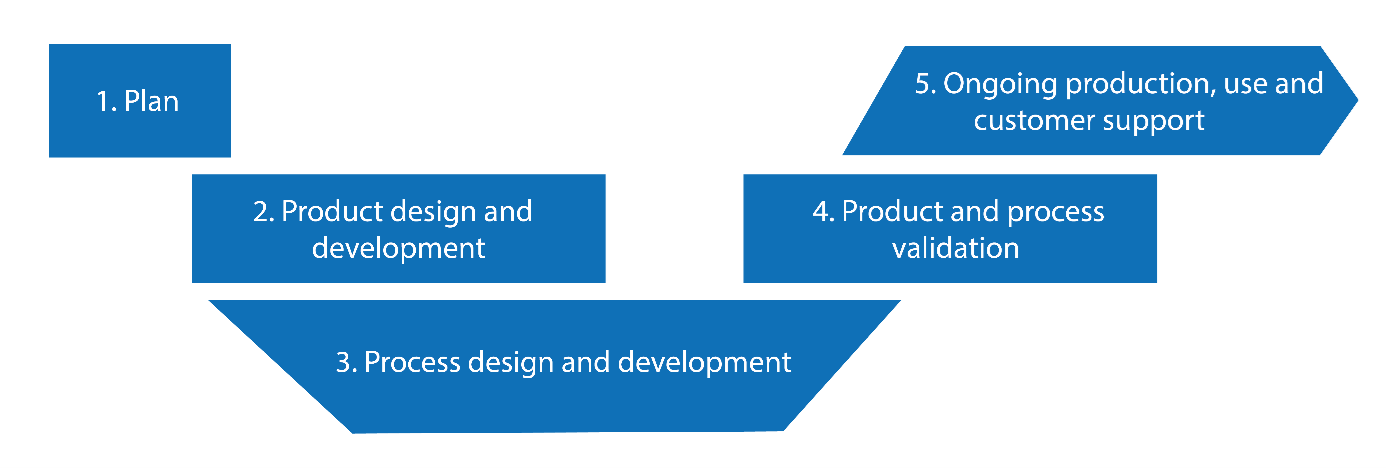

2.) PHASES OF THE APQP

3.) APQP SUITABILITY

Basically, the APQP approach is suitable:for new and for running projects and programmes,

4.) OUR SERVICES IN THE FIELD OF EN APQP

- We train your employees on EN 9145 “Requirements for advance product quality planning and the production part release procedure”.

- We evaluate your projects on the basis of the EN 9145 under consideration of aviation legislation requirements.

- We perform GAP-Analysis in your planning and initiate corrective actions or implement them together with you (e.g. avoidance of parallel and competing processes).

- We support you in the development of concepts for the transfer of APQP requirements to your supply chain.

- We support you in communicating with customers who demand the introduction of APQP, with the goal of making the introduction of APQP meaningful and based on already established processes.