1.) WHY IS A DESIGN ORGANIZATION NEEDED?

Anyone intending to develop products (aircraft, engines, propellers) or modifications to products and associated parts and equipment (such as structural elements, landing gear, avionics and other parts) or ETSO articles in accordance with the applicable design standards (CS – Certification Specification) requires approval as a design organisation in accordance with (EU)748/2012, Part 21, Subpart J (DOA).

This means that an legal entity or natural person (applicant) has demonstrated compliance with the applicable certification specifications (design standards for each aircraft category, environmental requirements, operational suitability data, and special conditions, if applicable) in accordance with the requirements of the applicable sections of EASA Part 21, Subpart J and other Subparts, e.g., A; B; D; E; K; P; and Q.

As evidence of compliance with the type-certification basis, the following certificates may be issued after certification:

- Declaration of Compliance or

- DDP (Declaration of Design and Performance. For ETSO articles only).

Proof of compliance must be provided in accordance with the approved procedures within the Design Management System (DMS).

However, if the product (aircraft, engine, propeller) or the modification to an already approved product is more complex and/or new, the requirements for the Design Management System (DMS) will be higher.

Notice. Please note that a Design Organization under Alternate Procedures (ADOA. Limited Design Activities Only.) must meet a simplified requirement per 21.A.14.

2.) OPTIONS FOR MEETING THE REQUIREMENTS OF PART 21 (DOA)

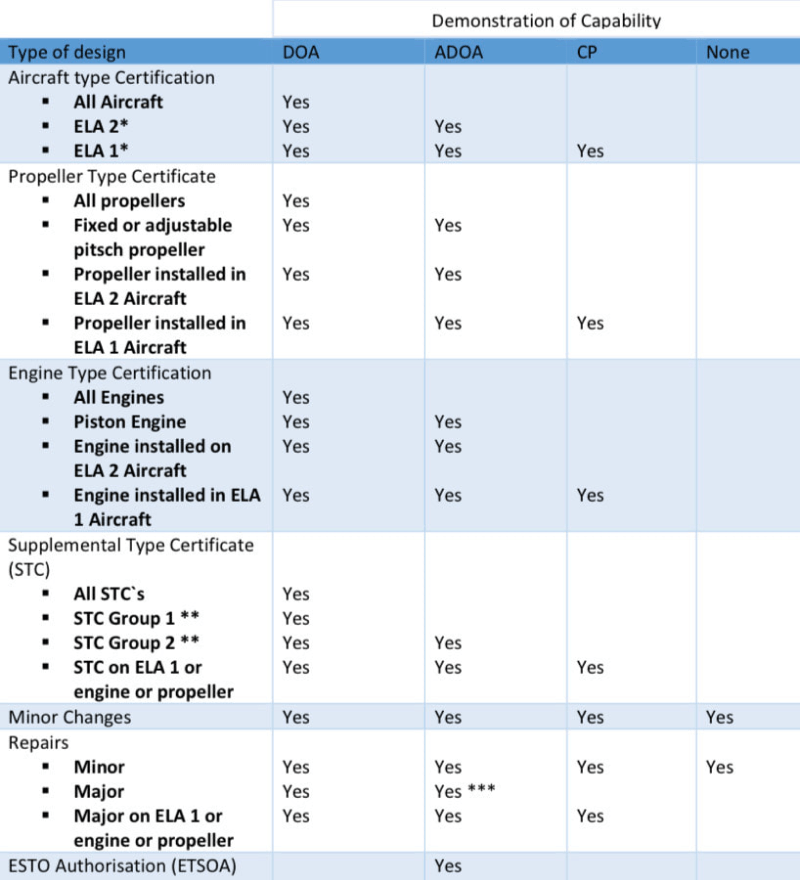

The following requirements may be met to demonstrate the organization’s eligibility for the desired approval for a particular design:

* For definitions see (EU) 748/2012 Article 1 ** For definitions see GM 21.A.112B *** Upon Agency agreement Quelle: EASA

3.) DESIGN MANAGEMENT SYSTEM (DMS)

The DMS is a system for controlling and monitoring the design, design changes to products and parts that fall under the conditions of approval.

A component of the DMS is the Safety Management System (SMS). The objective of the SMS is to identify and assess hazards to product, its modification or design organization in terms of aviation safety and to manage the associated risks, including risk mitigation measures, and to verify their effectiveness. In short, the established technical organizational and personnel requirements must cover the EASA Part 21 Subpart J requirements. The DMS must control all external organizations (such as design subcontractors) involved in design activities. The DMS is based on two pillars:

- Design related: Independent design review (“4-eyes principle”) by CVE (Compliance Verification Engineer).

- DMS related: Independent System Monitoring Function (ISM)

4.) THE PATH TO BECOMING AN APPROVED DESIGN ORGANIZATION (DOA)

To establish a Design Organization (DO) under EASA Part 21 Subpart J, you will need:

- Provide technical, organizational, and personnel requirements in accordance with EASA Part 21 Subpart J,

- Design Manual (DOH) describing the DMS considering the relevant requirements of EASA Part 21 Subpart J, A, B, E, D, K, P and Q,

- Flight Test Operations Manual (FTOM), only for design organizations that are developing new products or modifying existing products and need to perform test flights.

5.) ACC SERVICES IN THE AREA OF PART 21, SECTION J (DOA)

We assist our customers in establishing Part 21, Subpart J and attainment of authorization (DOA) development operations, including:

- developing or providing high-quality generic design organization manuals tailored to your organization and type of development activities,

- Developing or providing high-quality flight test operation manuals (FTOMs),

- Training and coaching of personnel,

- Gap analysis (implemented design system vs. requirements of EASA Part 21, Sections J, A, B, E, D, K, P, and Q,

- Conduct internal audits, including pre-approval audits prior to official EASA approval audits in Phase 3 (prior to 3rd checkpoint),

- Interim management for ISM function,

- Support of EASA audits and meetings.