1.) DEFINITION

The objective of safety management is to identify hazards to aviation safety and to mitigate or prevent the associated safety risks before they lead to accidents or incidents. Safety management enables an organization to manage its activities in a more systematic and focused manner. When an organization has a clear understanding of its role and contribution to aviation safety, it can prioritize safety risks and manage its resources more effectively to achieve optimal results.

Safety management (Safety Management) is the responsibility of the entire organization, or the entire enterprise that unites individual or multiple aviation-related organizations.

The safety management system is based on the following elements:

- Safety Policy and Safety Objectives

- Commitment and responsibility of management,

- Safety responsibilities of managers,

- Designation of key persons responsible for the

- Coordination of emergency planning,

- SMS documentation (SMS procedures integrated into the QMS or an SMS manual).

- Safety Risk Management

- Hazard identification process,

- Process for risk analysis and mitigation.

- Ensuring safety

- Measuring and monitoring safety (compliance monitoring),

- Management of changes,

- Continuous improvement of the SMS.

- Promotion of safety

- Training (human factors, error management, procedures, etc.),

- Safety communication.

The requirements for SMS differ slightly between initial airworthiness ((EU)748/2012, Part 21, Subparts G and J) and continuing airworthiness ((EU)1321/2014, Part CAMO and Part 145).

2.) IMPLEMENTATION INTEGRATED MANAGEMENT SYSTEM (IMS).

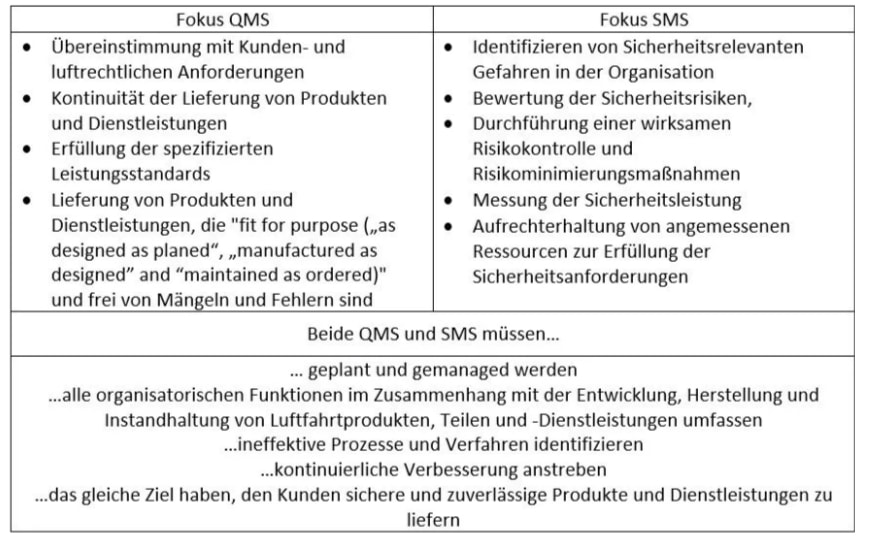

Quality Management Systems (QMS) structured in accordance with EASA Part 21, EASA Part 145, or EASA Part CAMO are generally compatible with SMS requirements.

The following overview shows the focus and compatibility of both systems:

In organizations that have multiple airworthiness approvals, consideration should be given to the possibility of implementing a cross-division safety management system (SMS) to avoid “competing” safety management (SM) processes and procedures.

3.) ACC SERVICES IN SAFETY MANAGEMENT SYSTEM (SMS)

- Perform a GAP analysis to determine the extent of management system non-compliance with SMS requirements based on Part 21, 145 and Part-CAMO requirements including AMC and GM,

- Development and definition of strategies for the introduction and sustainable implementation of SM requirements in your organization,

- Development of new manuals and procedures and adaptation of existing based on GAP analysis,

- training.